Livestock production operates under multiple pressures: reducing the use of antibiotic growth promoters, improving feed conversion efficiency with increasingly variable forages, sustaining gut health in the face of health challenges, and at the same time lowering the environmental footprint. In this context, probiotic microencapsulation has emerged as a technological tool capable of closing the gap between science and on-farm productivity.

Common challenges in livestock production (and why they harm performance)

Feed processing: pelleting or thermal conditioning involves temperatures >60–70 °C; humidity and mechanical compression are also common. These factors degrade beneficial microorganisms and reduce their viability before they reach the animal.

Storage and logistics: in hot/humid climates or with limited infrastructure, relative humidity (RH) and oxygen accelerate the loss of colony-forming units (CFU), shortening the shelf life of microbial additives.

Gastrointestinal (GI) transit: gastric pH (1–3), bile salts, and digestive enzymes destroy sensitive bacteria; if they do not reach the intestine in sufficient numbers, the probiotic effect is marginal.

Zootechnical variability: in the field, differences in management, initial weight, and forage availability introduce noise into results; achieving consistency between herds and farms is a challenge (your in vivo trials were precisely designed to test under variable conditions and still showed advantages).

What does microencapsulation provide?

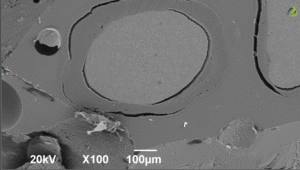

1. Shielding against heat, humidity, and compression

Encapsulation matrices (lipid blends/saponified fatty acids) create a physicochemical barrier that protects probiotics during processing, storage, and delivery. In the technical article (IJPP 2024), after subjecting Lactobacillus to stress and then simulating GI transit, encapsulated cells maintained markedly higher survival rates than non-encapsulated ones:

- Heat: after simulated GI transit, encapsulated probiotics retained ~79%, 65%, 39%, and 25% viability following pretreatments at 40, 60, 80, and 100 °C, respectively; non-encapsulated cells showed no viability under these conditions.

- Humidity: at 70% RH for 10 days, encapsulated strains retained ≈41% viability after GI simulation, versus 38% in non-encapsulated; by 20 days, none exceeded 10%, highlighting the severity of prolonged water stress. At 35% RH, encapsulated strains also outperformed non-encapsulated at 10–20 days.

- Mechanical stress: after 1 and 3 tons of compression + GI simulation, encapsulated probiotics reached ≈93% and 32% survival; non-encapsulated showed 68% and 0%.

2. Targeted release in the intestine

GI simulation data indicate that release occurs under higher pH with enzymatic action—exactly where the probiotic needs to act. The capsule works as a “gatekeeper,” preventing premature destruction in the stomach and delivering the content into the intestine, supporting colonization and interaction with the microbiota.

3. Longer shelf life and consistent dosing

At 25 °C/70% RH, encapsulated strains maintained ≈82% viability at 10 days and 31% at 20 days (direct measurement), while non-encapsulated strains dropped over time. At 35% RH, both decreased at 40 days, highlighting the importance of controlling RH, though encapsulated strains consistently performed better under GI simulation. In practice, this means more predictable rations (what you formulate is what actually reaches the animal alive).

Does it translate into animal performance?

Yes. The use of an encapsulated probiotic consortium was associated with an increase of 115 g in daily weight gain (DWG) compared with sodium monensin, in line with in vitro and simulation results. In addition, greater degradability of NDF and ADF (neutral and acid detergent fiber) was reported in fermentation systems, consistent with a more fibrolytic microbiota and favorable pH in RUSITEC fermenters. This is particularly strategic in forage-based systems: more degraded fiber = more metabolizable energy and better feed conversion.

From an operational standpoint, replacing or complementing antibiotic growth promoters with encapsulated probiotics improves feed efficiency and can contribute to lower energy losses and reduced fermentation emissions (e.g., methane), aligning productivity with sustainability.

Conclusion

Modern livestock production requires robust tools that withstand real-world stressors (heat, humidity, compression, gastric acid) and deliver benefits where they matter most: in the intestine. Microencapsulation fulfills that promise with solid data: better post-processing and post-GI viability, greater storage stability, and verifiable zootechnical improvements (e.g., +115 g/day in DWG vs. monensin in your trials). For beef and dairy systems seeking efficiency and sustainability, it is a technological lever ready to scale.

Want to dive deeper?

Explore our research page and learn in detail how probiotic microencapsulation is transforming animal nutrition.