Currently there is a worldwide trend towards the banning of the use of antibiotics as animal growth promoters and as a prophylactic treatment to prevent diseases during the animal’s growth stages. This trend is not capricious, but responds to the appearance of pathogenic bacteria resistant to antibiotics, a phenomenon known as antimicrobial resistance (AMR), which is potentially harmful to humans.

This new reality has boosted the development of antibiotic-free growth promoter feed additives as the main nutritional strategy to deal with this problem. That is why today we have a market flooded with products that promise high profitability in the production of animal proteins and that are responsible for the health of the final consumer, based on very good results in laboratory and experimental farms tests, but with poor reproducibility in commercial farms.

Why are the results of experimental farms not reproducible in commercial farms?

The answer to this question includes various factors, from differences in farm management, environmental conditions, genetic characteristics of the animals and, very commonly, the way additives are supplied.

I wish to emphasize this last cause, since it is usual that in the experimental tests the additives to be evaluated are supplied individually to each animal, added as a topping in the feed and dosed shortly before being consumed, without being exposed to periods of storage or transport, conditions that are difficult to repeat on a commercial farm.

The reason why additives have this special handling during trials, especially freeze-dried probiotics and some natural extracts, is because they are affected by long storage periods, high process temperatures applied in the production of concentrated foods (pelletized, baked and/or extruded) and also by the conditions of the digestive processes.

What are the challenges for an effective additive?

For an additive to be effective on a commercial farm, it must be guaranteed that it retains its initial activity or the highest percentage of it after being added and thermally processed in feed matrixes (extrusion, pelletizing, baking, etc.), to withstand long storage times exposed to oxygen, humidity, light, room temperature and, in the particular case of probiotics, to withstand gastric conditions (pH, temperatures, gastric enzymes) to be released in a controlled manner in the intestine.

Furthermore, evidence indicates that a mixture of cooperating strains is more effective than a single strain. Even the most recent studies show that the effectiveness can be enhanced if the additive consists of probiotics, prebiotics, essential oils, and organic acids that interact synergistically, a mixture known as eubiotics. Unfortunately, almost all of these molecules are unable to withstand the adverse conditions described above.

Solutions

Among the ingredients that meet all the resistance characteristics required for an additive, only some sporulated microorganisms could be mentioned, such as, for example, Bacillus subtilis or prebiotics such as the yeast cell wall, but not many more.

Well, considering that eubiotic mixtures are the most effective ones, encapsulation technologies that protect those other thermosensitive or thermolabile additives become relevant.

These technologies involve coating sensitive active ingredients within a shell, which can release its contents at controlled rates once activated by an external stimulus (e.g. temperature, pH, enzymes, etc.)

Short overview of encapsulation methods:

It is important to keep in mind that not all encapsulation technologies are the same, nor are they applicable to all active ingredients, but they can be divided into two methods mainly: physical-mechanical such as spray drying and physical-chemical such as extrusion or emulsion.

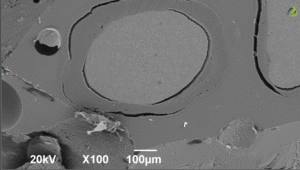

Spray Drying: The principle of the spray drying technique consists of dissolving a polymer, in the continuous phase (generally water), which surrounds the particles of the active ingredient within sprayed drops. The drying process causes this solution to shrink into a sheath of pure polymer that encloses the core material. The resulting capsules are obtained as free-flowing dry powder.

Emulsion: It consists of adding a small volume of the polymer-active ingredient suspension to a large volume of vegetable oil. The mixture is then homogenized to form a water-in-oil emulsion. Once the water-in-oil emulsion is formed, the water-soluble polymer must be insolubilized to form minute gel particles within the oil phase. The chosen insolubilization method depends on the type of support material used. The beads are then collected by filtration.

Extrusion: The principle of this technique consists in preparing a hydrocolloid solution, adding the probiotic ingredient to the solution and dripping the suspension through a syringe needle or a spray machine with a nozzle in the form of drops that are allowed to fall freely into a solution bath or hardener. The hardened pearls are then collected.

| Spray drying | /Extrusion | /Emulsion | |

| /Scale up | Easy | more difficult | Easy |

| Encapsulation process | Simple | Simple | hard |

| Coating materials | Many | Few | Many |

| Size and shape | Uniform and small | Uniform and big | Not uniform and small |

| Survival of microorganisms | low | High | High |

Each of the techniques described above can generate capsules with different characteristics depending on the coating materials used and the variables in the process, information that could be expanded on in another blog.

Bialtec disruptive technologies:

At Bialtec we are aware of these challenges and in response we have developed a technology that we call “micro-encapsulated precision microbiomes”.

Precision microbiomes: It consists of taking Eubiotic mixtures to a new level of development, since it is not a mixture of ingredients but consists of a community of microorganisms that are carefully cultivated together in a bioreactor, to later be harvested and lyophilized. This technique allows to obtain additives with very high diversity adapted to coexist cooperatively and with multi-effect action.

Bialtec microencapsulation: Patented technology for coating precision microbiomes that mixes emulsion and spray techniques, in such a way that it protects them during the process of preparing and storing the compound animal feed, thus facilitating its addition to food matrices. In addition, this microencapsulation protects the microbiomes from the conditions of gastric digestion, to finally release them in a controlled manner in the intestine, allowing its effective colonization.

Conclusion:

Perhaps at this point you feel that you have received a lot of information, remember that you can return to this blog as many times as you need to consult again, but I want to highlight three important conclusions:

- An additive based on a eubiotic mixture is more effective than a single isolated component

- The vast majority of eubiotic additives, if they do not have a coating that allows them to withstand the conditions of feed preparation, storage and gastric digestion, will be useless when applied on a commercial farm. In other words, it is useless for an additive to contain a wide variety of very powerful components if they are not protected in some way, as they will degrade before reaching their point of action.

- Encapsulation methods offer a great alternative to protect additives, but it should be noted that not all techniques are the same or applicable to all conditions.