Microencapsulation is a crucial technique in the protection and controlled release of probiotics. In this study, we explore the use of microencapsulation to improve the viability of Lactobacillus acidophilus and Lactobacillus casei when exposed to various environmental and processing conditions.

Microencapsulated probiotics can be an effective method for producing stable preparations that retain functional properties!

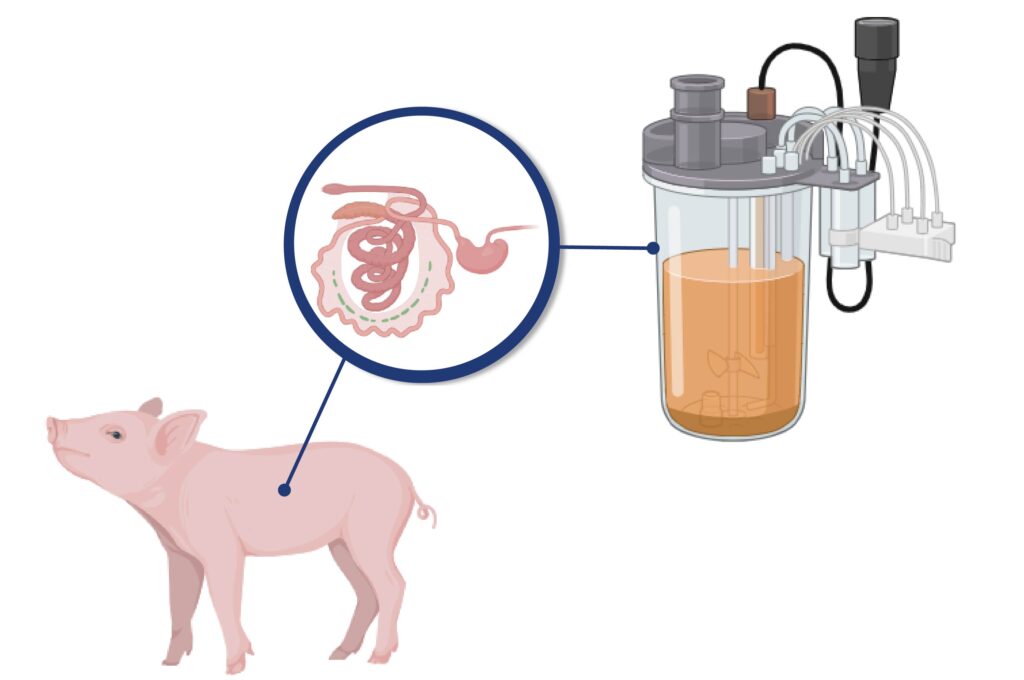

Simulated Gastrointestinal Tract

The microorganisms used in this study were Lactobacillus acidophilus and Lactobacillus casei. These probiotics are known for their digestive health benefits and are commonly used in supplements and functional foods (FAO/WHO, 2002).

To evaluate the controlled release of microencapsulated probiotics in the intestine, we designed a system similar to the gastrointestinal tract of monogastric animals, including stages of exposure to different levels of acidity and digestive enzymes.

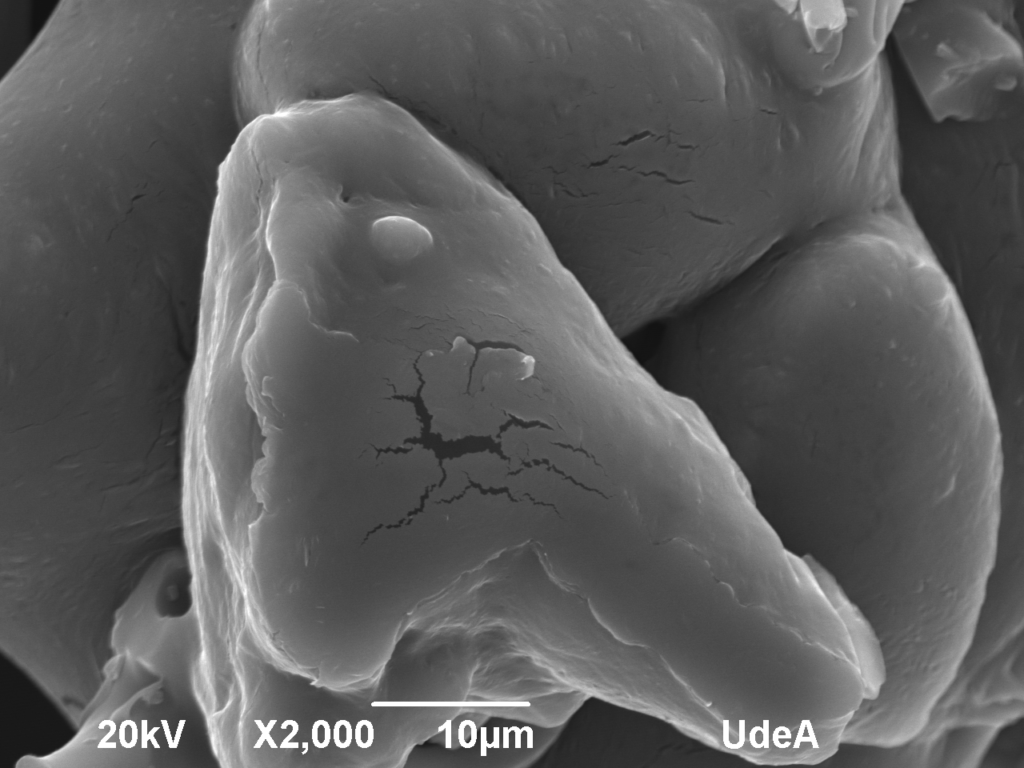

Characterization

We characterized both microencapsulated and non-encapsulated microorganisms using two main techniques:

- Scanning Electron Microscopy (SEM): This technique was used to observe the morphology of the microencapsulated samples.

- Plate Counting Method: The residual viability of the microencapsulated samples was determined using the standard plate counting method. In recent years, researchers have documented the results of incorporating probiotics into diets.

Results

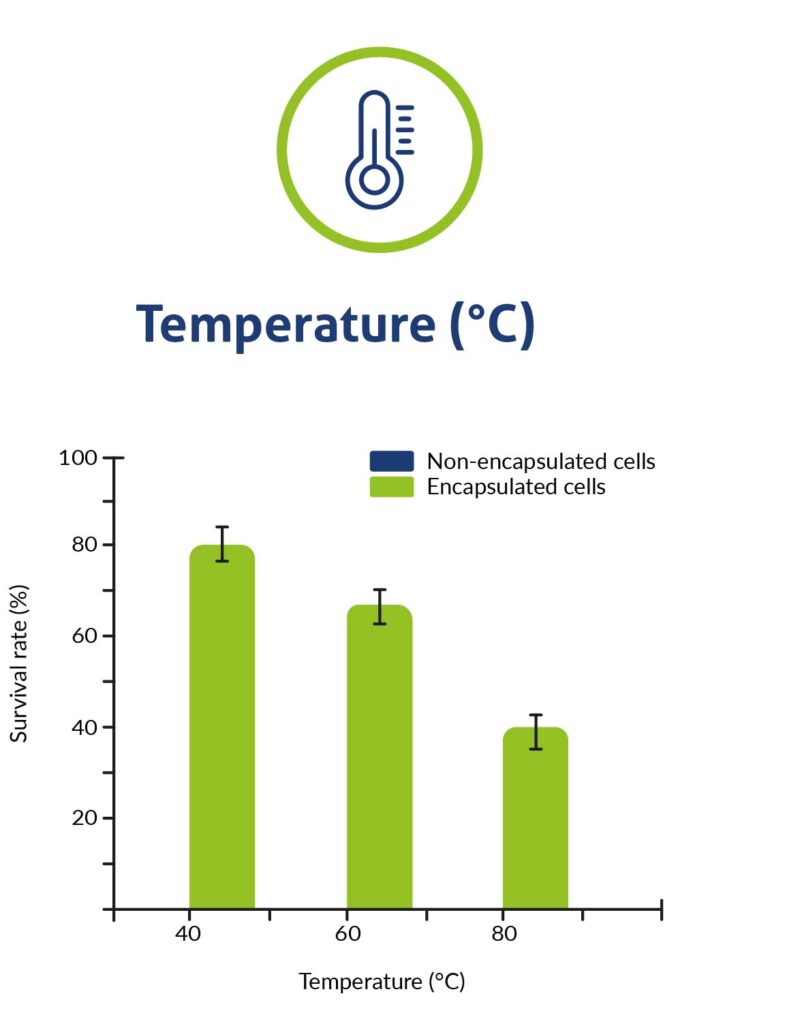

Survival Rates after Heat Exposure

Encapsulated and non-encapsulated microorganisms were exposed to thermal stress conditions at various temperatures. The survival of probiotic microorganisms was evaluated after being subjected to simulated gastrointestinal conditions. The results showed a remarkable difference between encapsulated and non-encapsulated microorganisms, where non-encapsulated cells lost all viability after being subjected to thermal, chemical, and enzymatic conditions. Notably, our microencapsulated microorganisms showed viability even after being subjected to 80°C and gastric conditions, indicating that the protection of probiotics is effective in pelletization and/or extrusion processes in food.

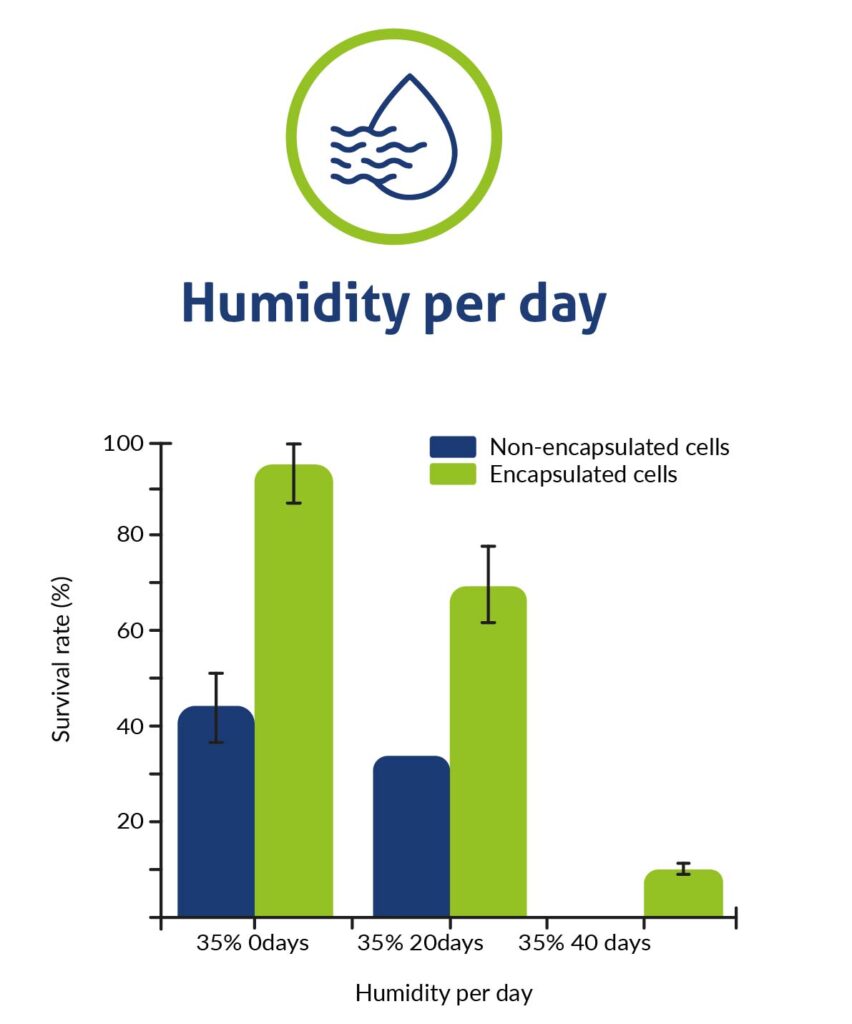

Survival Rates after Humidity Exposure

Encapsulated and non-encapsulated probiotic microorganisms were exposed to storage conditions with different humidity levels (70% and 35%). Again, the viability of the microorganisms was evaluated after being subjected to simulated gastrointestinal conditions. It is evident that microencapsulated microorganisms with our technology have higher survival rates after being subjected to various storage conditions for several days.

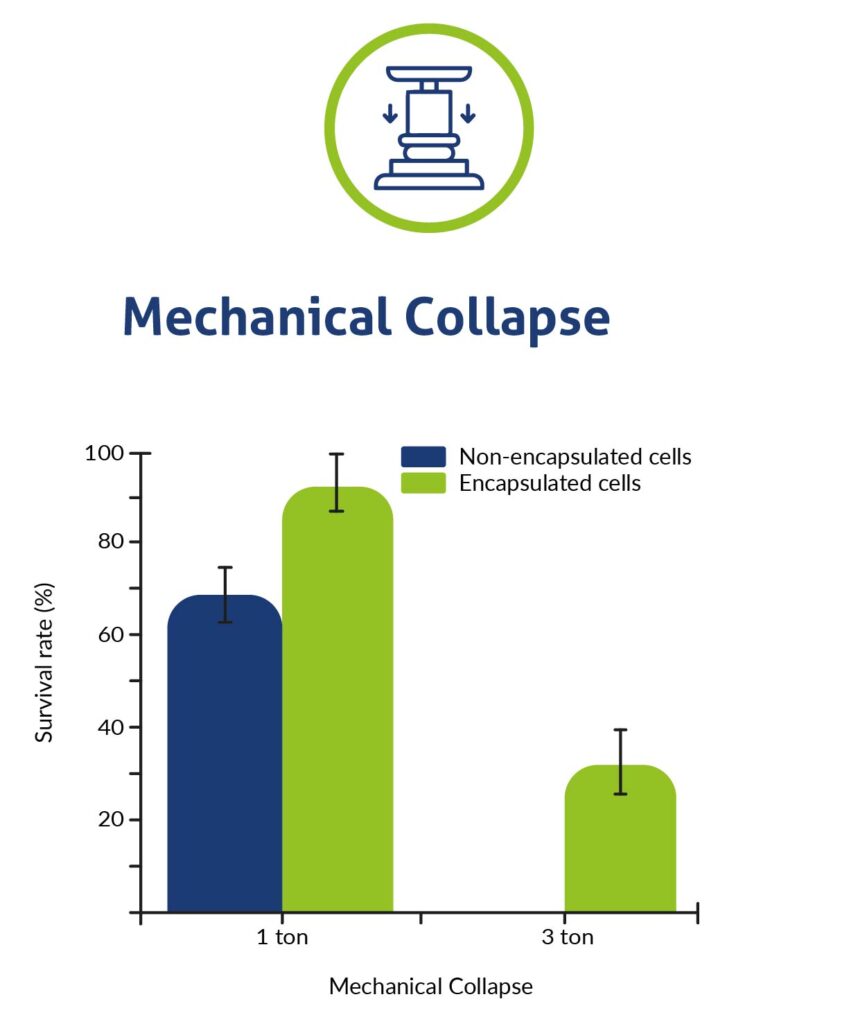

Survival Rates after Mechanical Stress Exposure

Finally, encapsulated and non-encapsulated microorganisms were exposed to different mechanical force conditions. Their viability was evaluated after being subjected to simulated gastrointestinal tract conditions. The results indicated that microencapsulated microorganisms have a higher survival rate compared to non-encapsulated microorganisms. These results, combined with thermal tests, reinforce the advancements in our probiotic encapsulation technology, which can be used in pelletization and/or extrusion processes in animal feed.

Conclusions

Microencapsulation of Lactobacillus acidophilus and Lactobacillus casei proved to be an effective technique for improving the viability of these probiotics under adverse conditions. These findings highlight the importance of microencapsulation in the formulation of supplements and functional foods that aim to maximize the digestive health benefits of probiotics.

Additionally, microencapsulated probiotic microorganisms showed notable resistance to high temperatures, storage conditions, and mechanical stress, suggesting that microencapsulation can be an effective strategy for protecting probiotics during processing and storage. Furthermore, it is important to note that all viability tests of the microorganisms were conducted after being subjected to a simulated gastrointestinal process to demonstrate the total recovery of the probiotic after being processed by the animal. It is evident that the microencapsulation technology employed not only improves the stability and release of active ingredients but also optimizes animal health and performance, contributing to more efficient and sustainable livestock production.

If you want to know more details about the results of this study, we present our scientific article Microencapsulated Powder Lactobacilli: An Approach to Producing Probiotics Resistant to Different Stress Conditions.

References

FAO/WHO. (2002). Guidelines for the evaluation of probiotics in food. London, Ontario, Canada, April 30 and May 1, 2002. 1–11.